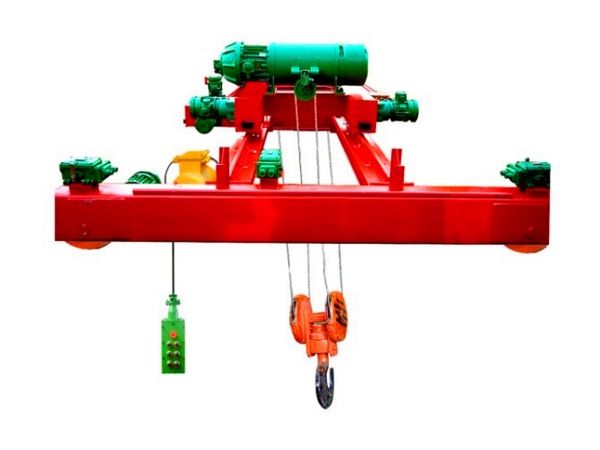

Stacking crane

Source manufacturer

technological innovation

High cost performance ratio

The intelligent bridge type palletizer is widely used in the warehouse stacking and palletizing of enterprises in industries such as grain, flour, starch, oil, fertilizer, feed, salt, cement, etc. It effectively solves the problems and drawbacks of large warehouse stacking workload, high labor intensity, high labor demand, low work efficiency, and high production costs, and can greatly improve the equipment technology and management level of production enterprises.Performance characteristics:Easy to operate, reliable to run, easy to manage, effectively reducing production costs.The utilization rate of warehouse capacity is high, and the stacking height is determined based on the warehouse height and customer requirements.Structurally, the vertical movement of the large crane and the horizontal movement of the small crane, as well as the lifting and rotation of the lifting conveyor, ensure that the palletizer can stack packages at any position in the warehouse.The drive motors of each conveyor are matched with frequency converters to effectively limit current, stabilize voltage, and regulate speed.Multiple packaging scales are equipped with anti stacking and anti-collision bag control devices between the conveyor and the collection conveyor to ensure smooth bag transportation.Adopting imported high-quality sensors and equipped with a photoelectric counter system, it records the quantity and cumulative quantity of shift production, daily production, monthly production, and accurate counting.Based on PLC control, the fault alarm device and online control system can control the palletizing and conveying control system to stop in sequence from front to back in case of machine failure, blockage, or other abnormal phenomena, promptly eliminate faults, and ensure the reliable operation of the system.The on-site monitoring and control components for palletizing are made of Siemens brand, and the touch screen displays various on-site information intuitively, with simple and convenient operation; The control system has remote monitoring and control functions, which can remotely monitor the working conditions of the palletizing site and facilitate management.It has multiple communication interfaces and can provide a highly flexible and scalable control platform according to user requirements for remote production maintenance, production monitoring, and production management. It can also transmit factory data to other MIS management information systems or MES production execution systems to complete data storage, classification, and management.Specification parameters:Applicable warehouse width: 12-30mBag weight: 10-70KgStacking height: 3-6mStacking speed: 600-1500 packages/hour