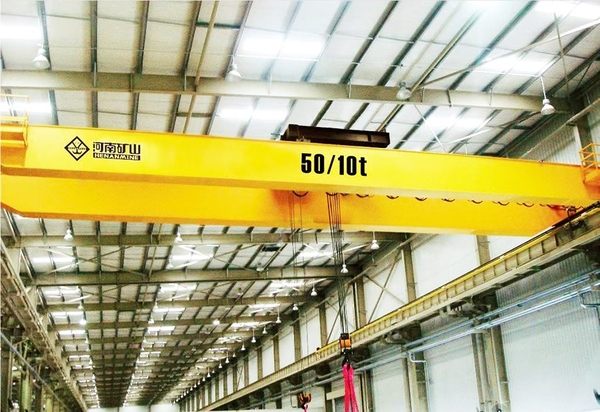

New type of electric hoist bridge crane

Source manufacturer

technological innovation

High cost performance ratio

The new type of bridge crane is a lightweight, universal, energy-saving, environmentally friendly, maintenance free, and high-tech crane developed by our company based on the introduction and digestion of foreign * * technology, guided by modular design theory, modern computer technology, and optimized design and reliability design methods. It is completed using imported configurations, new materials, and new processes. The design, manufacturing, and inspection of this crane are in accordance with the newly issued national standards, equivalent to some foreign standards such as FEM, DIN, IEC, etc. Compared with the original universal QD bridge crane products, the self weight is reduced by about 15-30%, and the large wheel pressure is reduced by about 10-35%, which can reduce the requirements of the crane on the factory structure and save the manufacturing cost of the factory. The core component of the transmission mechanism, the reducer, all adopts hard tooth surfaces and high-precision gear pairs, coupled with the application of steel drums, forged wheels, and variable frequency speed control systems, making this model of crane an upgraded product with excellent economic and social benefits, suitable for industries such as mechanical manufacturing, assembly, petrochemicals, warehousing and logistics, power construction, papermaking, and railways. The main beam adopts a skewed box structure and is connected to the end beam with high-strength bolts for easy transportation** The chemical processing equipment ensures the accuracy of the main end beam connection, ensuring smooth operation of the crane.Ø The lifting trolley is an open compact winch structure, and European style hoist trolleys can also be used for small and medium tonnages. The large and small car operating mechanisms adopt a European technology three in one drive form, with a hard toothed reducer, compact structure, low noise, no oil leakage, and long service life.Due to the use of European compact cars and high-strength materials, the overall dimensions of the machine are small and lightweight. Compared to traditional cranes, the height of the factory building can be reduced under the same lifting height conditions, effectively reducing the cost of the factory building.Modular design, short design cycle, high degree of universality, and improved utilization of components.Compact structure, low clearance, small external dimensions, large working range, effectively improving production efficiency.Ø Fully variable frequency control, smooth operation, no impact, slow heavy load, fast light load, energy-saving and consumption reducing.